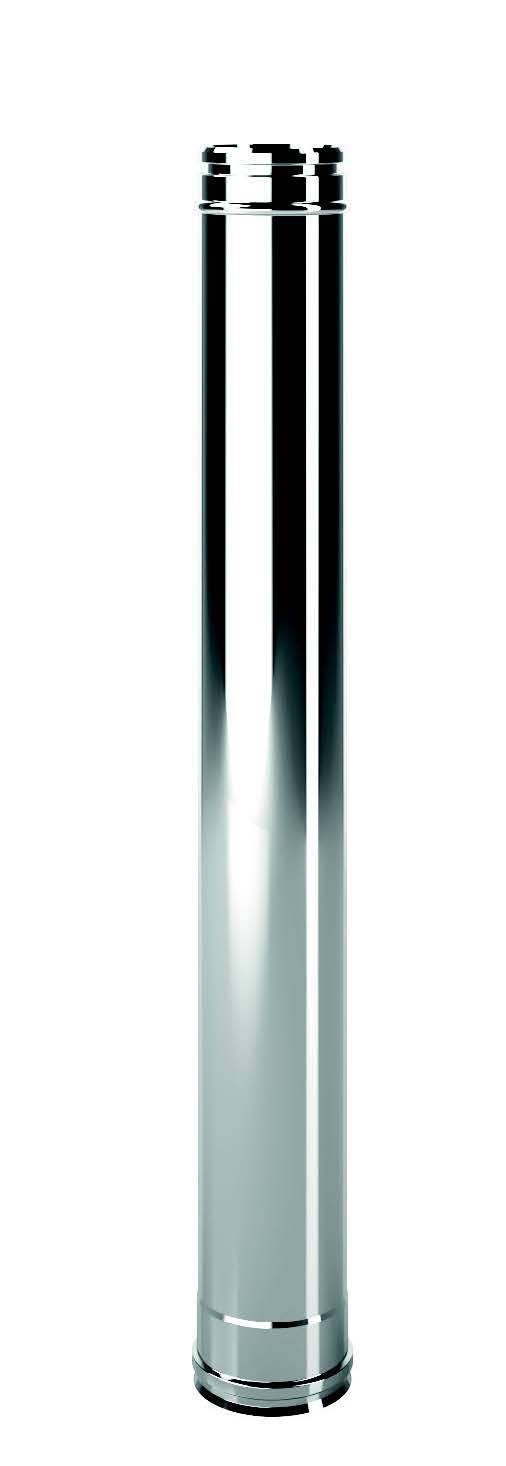

Internal wall in AISI 316L stainless steel, external wall in AISI 304 Stainless steel or natural copper with static air cavity insulation: introducing ISO AIR. One of the least bulky insulating systems in the category, ISO AIR stands out for combination with boilers, including condensing boilers, pellet stoves, thanks in part to the soot-fire resistance test (“G”) which is compulsory in accordance with current prevailing standards and passed with flying colours. The range is substantiated with the possibility of painting the product with the widest variety of colour schemes, including the HAMMERED COPPER finish which undoubtedly stands out from the rest.

T200-P1-W-V2-L50040/050-O40

Flue system / flue-duct resistant up to 200 Pa and wet fumes

T600-N1-W-V2-L50040/050-G300

Flue system with high temperature, wet or dry fumes and negative pressure too